- Home

- Support

- Case Studies

- 1004

Code

1004

The Challenge

The customer machines flamecut A36 mild steel plate weldments using a radial arm drill machine with flood coolant.

Because this drilling operation was ineffective, the customer requested a solution to improve performance.

The T-A significantly improved the customer’s process, providing substantial cost savings from multiple areas of the operation.

| Product: | T-A |

| Objective: | Improve performance |

| Industry: | Structural steel/fabricator |

| Part: | Flamecut weldments |

| Material: | A36 mild steel plate |

| Hole Ø: | 2.5" (63.5mm) |

| Hole Depth: | 4.0" (101.6mm) |

The Solution

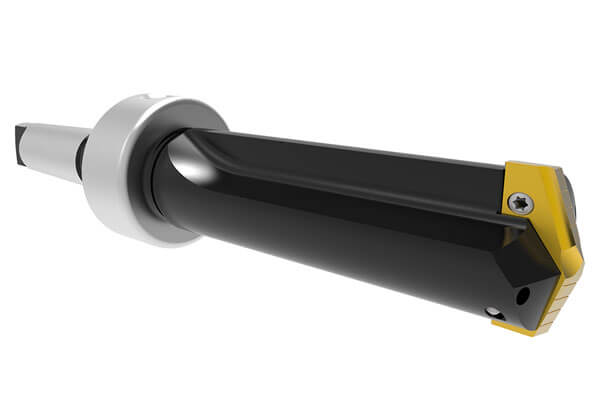

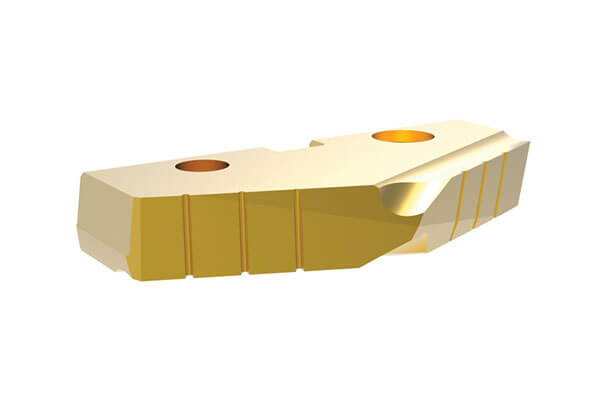

The T-A Drill

- Holder: 22050S-005I

- Insert: 135T-0216

| Measure | Competitor Drill | T-A |

|---|---|---|

| RPM | 60 | 115 |

| Feed Rate | 0.003 IPR (0.076 mm/rev) | 0.012 IPR (0.305 mm/rev) |

| Penetration Rate | 0.18 IPM (4.572 mm/min) | 1.38 IPM (35.052 mm/min) |

| Cycle Time | 22 min 13 sec | 2 min 54 sec |

| Tool Life | 75 holes | 300 holes |

| The T-A offered 86.25% cost per hole savings over the competitor tooling. | ||

The Advantages

The T-A provided:

- 300% tool life increase

- Decreased cycle time

- Decreased cost per hole