- Home

- Support

- Case Studies

- 1006

Code

1006

The Challenge

A customer is a large structural steel and ductwork specialty contractor in the construction industry. They manufacture I-Beams and H-Beams made from structural steel using a Peddinghaus with soluble oil mist coolant. The customer’s annual production is over 100,000 tons (90,718.5 metric tons) of steel beams, bars, and ductwork.

The customer wanted to increase productivity while decreasing the overall cost of production.

The T-A structural steel solution reduced the machine’s cycle time and also lowered the cost of production while increasing the overall productivity.

| Product: | T-A |

| Objectives: | (1) Increase productivity (2) Decrease cost |

| Industry: | Structural steel/fabricator |

| Part: | I-beams and H-beams |

| Material: | Structural steel |

| Hole Ø: | 1.1875" (30.163mm) |

| Hole Depth: | 0.8" (20.32 mm) |

The Solution

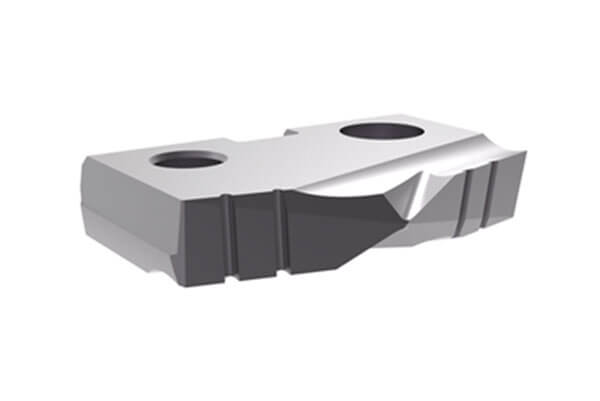

The T-A Drill

- Holder: 24020H-004IS100

- Insert: 152A-0106-SS

| Measure | Competitor | T-A |

|---|---|---|

| RPM | 350 | 320 |

| Speed | 109 SFM (33.223 M/min) | 99 SFM (30.175 M/min) |

| Feed Rate | 0.003 IPR (0.076 mm/rev) | 0.011 IPR (0.279 mm/rev) |

| Penetration Rate | 1.05 IPM (26.67 mm/min) | 3.52 IPM (89.408 mm/min) |

| Cycle Time | 45.7 sec | 13.6 sec |

| Tool Life | 500 holes | 500 holes |

The Advantages

The T-A provided:

- 70% cycle time decrease

- Decreased cost

- Increased productivity