- Home

- Support

- Case Studies

- 1009

Code

1009

The Challenge

A customer manufactures orthopedic instruments and implants for the medical industry. They use a HAAS VMC with water soluble coolant to produce their products. The part being machined is an orthopedic component made from stainless steel designed to support a human vertebral column.

The customer wanted to remain with Allied products, and they requested a solution to further improve the hole finish and increase tool life.

The T-A geometry and coating successfully improved the tool life and the hole finish.

| Product: | T-A |

| Objectives: | (1) Increase tool life (2) Improve hole finish |

| Industry: | Medical |

| Part: | Orthopedic component |

| Material: | Stainless steel |

| Hole Ø: | 0.437" (11.1mm) |

The Solution

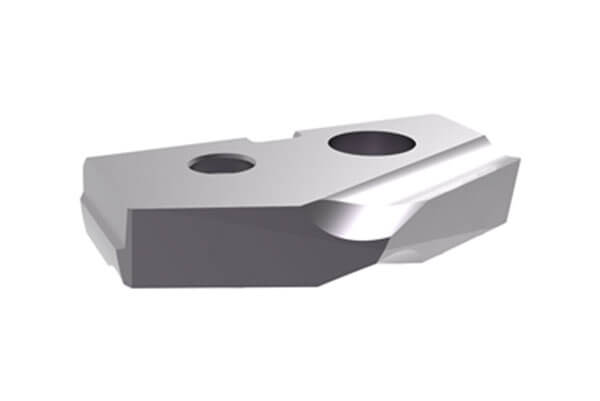

The T-A Drill

- Drill insert: 180A-13-NC

| Measure | Competitor | T-A |

|---|---|---|

| RPM | 250 | 280 |

| Feed Rate | 0.005 IPR (0.127 mm/rev) | 0.005 IPR (0.127 mm/rev) |

| Tool Life | 25 holes | 100 holes |

| Cycle Time | 4 min | 4 min |

The Advantages

The T-A provided:

- Provided 4x the tool life

- Improved hole finish