- Home

- Support

- Case Studies

- 1010

Code

1010

The Challenge

A customer manufactures printing rolls made from aluminum bar for the label industry. They use a Mori Seiki lathe with coolant through the tool to produce their products.

The customer needed to improve the production process by reducing the cycle time and decreasing the cost of production.

The T-A reduced the machine’s cycle time and lowered the cost of production.

| Product: | T-A |

| Objective: | Decrease cycle time |

| Industry: | General machining |

| Part: | Printing rolls |

| Material: | Aluminum bar |

| Hole Ø: | 1.00" (25.4 mm) |

| Hole Depth: | 10.0" (254 mm) |

The Solution

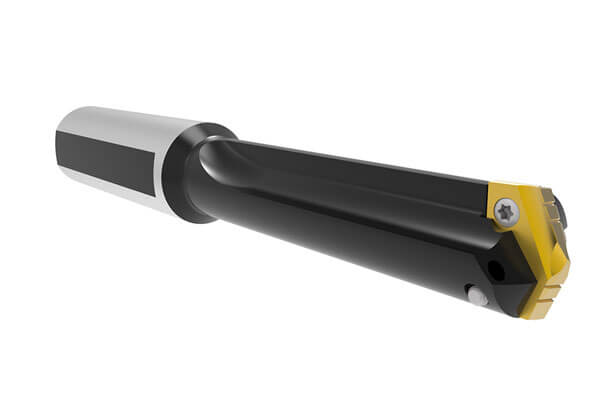

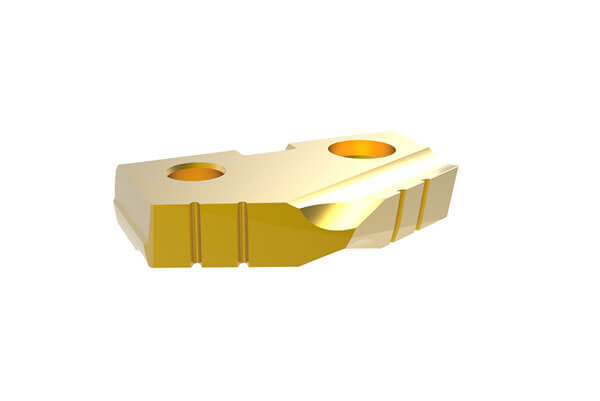

The T-A Drill

- Drill holder: 25020S-125L

- Drill insert: 1C22T-0100

| Measure | Competitor | T-A |

|---|---|---|

| RPM | 900 | 1800 |

| Feed Rate | 0.004 IPR (0.102 mm/rev) | 0.018 IPR (0.457 mm/rev) |

| Cycle Time | 55.56 sec | 18.52 sec |

| Dwell? | Yes | No |

| The T-A offered 61.86% cost per hole savings over the competitor tooling. | ||

The Advantages

The T-A provided:

- 61% cost savings

- Decreased cycle time

- Eliminated dwell stop

- Decreased cost per hole